NOVEL-ICE and DES/DX-CR

Units for Cold Environment Applications

Designed specifically to dehumidify low temperature spaces such as ice rinks and cold storage facilities this highly efficient system combines refrigerant based dehumidification with desiccant technology to dehumidify spaces kept at colder temperatures. The unique design allows the unit to achieve below freezing dew points with above freezing evaporator temperatures. The innovative method of using a desiccant wheel to move moisture around the evaporator results in a lower supply air dew point at a very high compressor COP of 5 – 5.5.

- High energy efficiency for cold environment applications

- Standard models available from 1000 - 12000 cfm

- Ideal for refrigerated warehouse and ice rink applications

Downloads

NOVEL-ICE Tech Sheet (ice rink applications, 4000cfm and below)

NOVEL-ICE Brochure (ice rink applications, greater than 4000cfm)

DES/DX-CR Tech Sheet (general-purpose, storage, lab and industrial applications)

600 DES/DX CR Tech Sheet (low-profile mounting for confined space)

How it Works

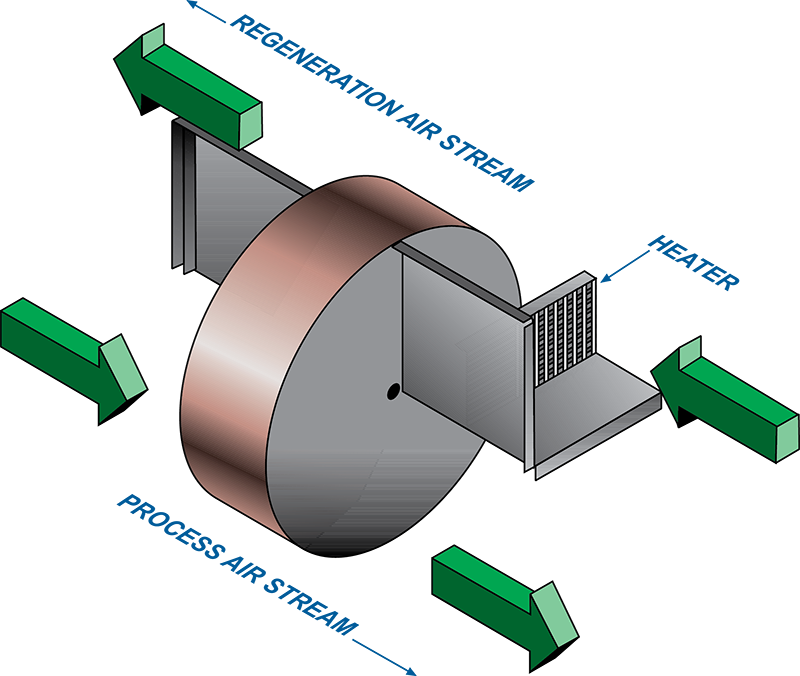

The units are comprised of a proprietary desiccant wheel positioned between the coils of a refrigeration circuit. Return air (or a blend of OA with RA) from the space flows across a condensing coil where it is heated.

The warmer air is then used to remove moisture from the desiccant wheel which increases the moisture content of the air prior to the evaporator coil. The evaporator coil wrings out moisture and the saturated air leaving the evaporator is then further dehumidified by the desiccant wheel. The ability of the desiccant wheel to move moisture around the evaporator coil allows the evaporator to operate at a higher temperature and the condenser at lower temperatures resulting in below freezing dew points at a very high COP.

As an option a second condenser may be used to reject heat outside the space. Additional options include exhaust air energy recovery, controlled outdoor air mixing for ventilation and pressurization, post-heating, post-cooling and upgraded filtration packages.

Energy Savings

Expensive gas fired desiccant units have traditionally been used to dehumidify ice rinks and other cold environments. Operating costs are high, the units are complicated to operate, and maintenance and first costs are high.

These new cold environment dehumidifiers can achieve comparable dew point performance with far less energy consumption. Simplicity of operation and low maintenance requirements differentiate it further from the gas fired type desiccant units.